Knowledge Base +

Knowledge Base +  2024.02.23

2024.02.23With the rapid development of 5G services, the entire network, from access to the core, must upgrade to higher data rates to meet the demands of the business. However, higher rates also mean higher power consumption. To reduce the operating expenses of operators, making networks more environmentally friendly and energy-efficient, power reduction in optical devices and transceiver modules has become a major factor in telecommunications and data center considerations.

In addition, to increase the speed of optical modules from 10Gbps to 100Gbps to 400Gbps and even 600/800Gbps, switching and processing technology (DSP switching core) has upgraded from 28nm to 16nm, 7nm, and soon-to-be-produced 5nm CMOS technology, to maintain a balance between overall power consumption and thermal budget.

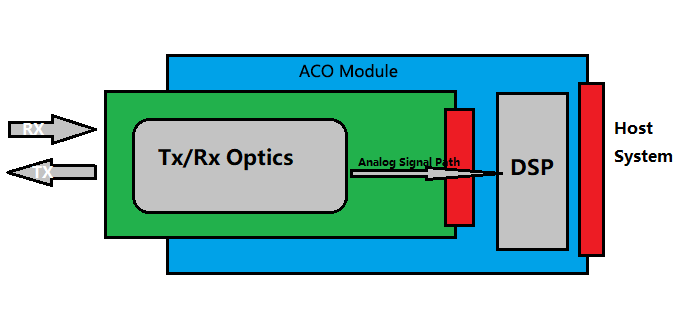

As we know, coherent transceivers rely on DSP to process optical signals. When DSP technology was initially introduced, its power consumption and thermal density were extremely high, to the point where optical devices and DSP had to be physically separated to prevent overheating. In other words, communication between modules and systems was analog. Thus, the Analog Coherent Optical Module (ACO) was introduced, as shown in the figure below.

Despite years of engineering design and optimization, the maximum data rate of the analog electrical connector for the module is still limited to 25Gbps. To achieve higher transmission rates, very large form factors or line cards are needed to accommodate the heat generated by the DSP. The development of DSP and optical integration allows the co-packaging of the digital signal interface (DSP) and optical devices, making digital communication between modules and systems possible. This led to the development of the Digital Coherent Optical Module (DCO).

Now, it is possible to achieve a 400G rate within the small OSFP and QSFP-DD size specifications by combining new DSPs and integrated optical components. Moreover, since the use of PAM4 50Gbps digital electrical interfaces on the host side is already mature, DCO modules can be easily embedded, avoiding the bandwidth and repeatability limitations of ACO modules and achieving a "plug-and-play" solution.

The core difference between DCO and ACO modules lies in the fact that DCO integrates the DSP chip directly onto the optical device and uses digital communication between systems, also solving the problem of interoperability between switches from different manufacturers. Additionally, due to the higher integration of DCO, as shown in the table above, some commercial products can achieve module power consumption as low as 18W or even lower, compared to ACO modules, DCO has lower power consumption.

(1).Tencent recently released a CFP2-packaged 400G DCO module that combines II-VI's latest coherent optical engine with Inphi's latest 7nm DSP, achieving high-performance 400G and 200G plug-and-play solutions, which is a typical example of a DCO module;

(2).Infinera's silicon photonics is also interesting, providing sub-carriers, one end is 400G, and the other end supports coherent 16x25Gbps;

(3).Xena-THOR 400G network tester provides 400Gbps/port traffic generation capability, meeting the performance testing requirements of QSFP-DD pluggable modules, as well as performance testing of related modules and DSP performance verification, and there will be summaries and sharing of some test cases and white papers on joint testing with manufacturers in the future, stay tuned.

Additional Learning Hub Resources

How to Choose 100G CFP4 Optical Module vs 100G QSFP28 Optical Module

400G OSFP To QSFP-DD DAC Latest Product Solution

Subscribe to the newsletter

for all the latest updates.

2-5# Building, Tongfuyu Industrial Zone, Aiqun Road, Shiyan Street, Baoan District, Shenzhen. China